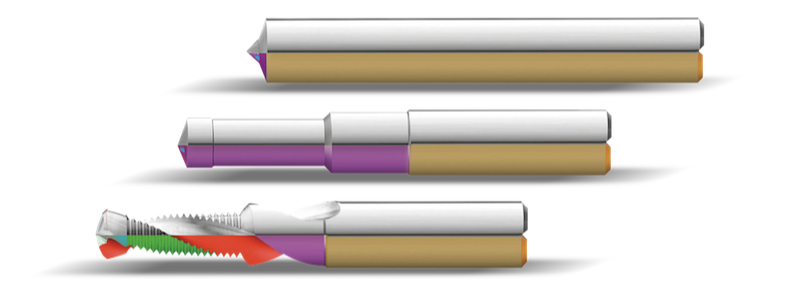

Our grinding machines cover the entire process chain of the tool. Precise and effective.

CNC control and drive systems from NUM as well as unified, graphically supported user interface NUMROTO for generating, simulation and production of complex geometries guarantee short set-up times, maximum precision and process reliability.

Wernesgrüner

Werkzeugsymposium 2024

12 – 14 March 2024

GrindingHub 2024

14 – 17 May 2024

Stuttgart, Germany

Hall 9 / Stand A70

MTA 2024

02. – 05.07.2024

SECC Saigon Exhibition

and Convention Center,

Ho Ci Minh City, Vietnam

IMTS 2024

9 – 14 September 2024

Chicago IL, US

MSV International Engineering

Fair 2024

8 – 11 October 2024

Brno Exhibition Centre, Brünn,

Czech Republic

ULMER WERKZEUGSCHLEIFTECHNIK succeeded J.E. REINECKER Maschinenbau in 1998.

Precision and performance are at the heart of the ongoing development of our machines.

We supply appropriate solutions to individual applications running on a modern machine program.

Our extensive experience in the field of tool grinding has made us valued partners for our customers.

Around 180 employees are working at our headquarters in Ulm-Einsingen, who design,

manufacture and market machine components and grinding machines.

Internationally, we work with our own sales offices and representatives in many countries in Europe and North America.

Our partners are supported by a service team and the application engineering team from our headquarters in Ulm.